To achieve the rapid clean energy transition, there is an urgent need for the sustainable supply of energy-relevant critical minerals and rare earth elements. Valuable energy-critical metals such as platinum group metals (PGMs) and Ni occur in low concentrations in mafic and ultramafic ores with complex mineralogy. PGM concentration, for example, is < 5 ppm (g/ton) disseminated in a large number of mineral phases (there are over 350 minerals that carry PGMs). These ores often contain low, but economically important, concentrations of other energy-critical metals such as Co and Cu. Traditional processing routes for these ores are energy and water intensive and require complex flow sheets and large amounts of diverse chemicals. Even then, a significant number of values end up in tailings because these values are disseminated in waste rock and not liberated; adequate liberation would require further extensive comminution which is both highly impractical and vastly uneconomical. There is thus a long-standing research need for innovative separation and extraction technologies for recovery and purification from both ores and tailings—especially from the latter, which have accumulated in vast ponds for many decades. Yet these mafic and ultramafic ores and their tailings, containing high concentrations of Mg, Ca, and Fe minerals (providing high carbon sequestration potential), provide a unique opportunity for developing innovative technologies in sustainable mining through the combination of energy-efficient carbon mineralization pathways for CO2 utilization and storage, in addition to renewable energy-driven recovery of metals.

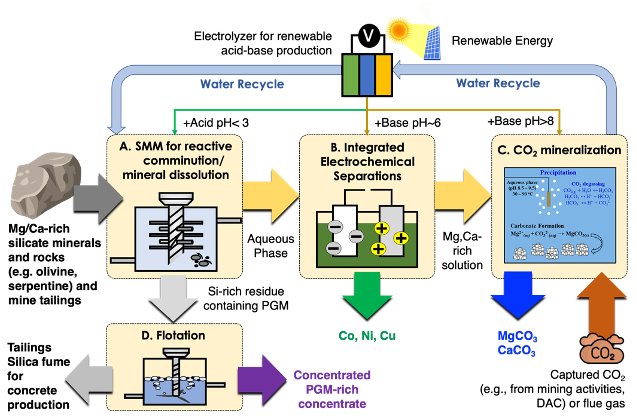

We envision a paradigm shift in sustainable mining by developing a more energy efficient, highly integrated, renewable-energy-driven CO2 sequestration and metal recovery technology for ores and especially tailings allowing tandem metal valorization and carbon sequestration. Specifically, our innovative concept aims to develop an autogenous, reactive comminution reactor system using Stirred Media Mills (SMM) that can provide excellent liberation of value minerals from host rock, thereby significantly enhancing their recovery and simultaneously also generate high specific-surface-area Mg/Ca/Fe (or Mg-Ca-Fe) silicate mineral particles for rapid leaching and continuous removal of Si-rich passivation layers on these silicates. In addition, this approach significantly reduces energy consumption in comminution (because the SMM will be operated at low speeds since the objective is not a targeted PSD) and can be coupled with sustainable carbon mineralization, flotation and electrochemical recovery of key energy minerals using selective redox pathways. LCSE core faculty members also combine novel reactor designs with electrochemical separation technology driven by renewable energy, creating a new pathway to recover energy-relevant materials from a wide range of unconventional resources including electronic wastes and waste-to-energy plant ashes.

Related projects:

- Integrated CO2-facilitated hydrometallurgical and electrochemical technology for sustainable mining and recovery of critical elements from wastes and ashes (LCSE PI: Alissa Park, collaboration with Xiao Su at UIUC)

- Electrochemical Production of Renewable Acids and Base for Sustainable Mining Future (LCSE PIs: Aaron Moment, Daniel Esposito, collaboration with Xiao Su at UIUC)

- Integrated Reuse and Co-Utilization of Slag, Sludge and Dust With Inherent Heavy Metal Capture and Nanoscale Calcium Carbonate Production as an Enhanced Fluxing Agent in Steel Plants (INSIGHT) (LCSE PI: Alissa Park, collaboration with Greeshma Gadikota at Cornell University)

- A novel approach to CO2 brick production integrated with simultaneous recovery of rare earth elements from carbon intensive industrial by-products (LCSE PI: Alissa Park, collaboration with Youngjune Park at GIST in Korea)

- Innovative Stirred Media Mill Reactor with Integrated Carbon Mineralization and Electrochemical Separation of Critical Metals (critical SMM-e) (LCSE PIs: Alissa Park, Aaron Moment, collaboration with Ray Farinato, D.R. Nagaraj, and Xiao Su at UIUC)

- Energy-Relevant Elements Recovery from CO2-Reactive Minerals during Carbon Mineralization (LCSE PI: Alissa Park, collaboration with Wencai Zhang at Virginica Tech and Hunter Vibbert)